COPC-2000

COPC standard is

specifically developed for call center industry and later extended to Business

Process Outsourcing (BPO) companies as well.Unlike ISO-9001:2000, this standard uses the language used in the call

center industry and also specifies the key customer-Related Processes (KCRPs)

and Key Support Processes (KSPs) to be controlled.Further, for each type of call center and BPO

it specifies detailed metrics to be controlled in the standard.

The companies implementing COPC need to achieve some benchmark

levels to get certified.Thus it is more

performance oriented and six sigma can help achieve these benchmarks.The following criterion is used for

certification of COPC standard:

-

Meet or exceed targeted performance levels for at least 50% of the metrics, and

-

Exhibit sustained improvement in a total of 75% of the metrics.

Further, meeting targeted performance levels is defined as

meeting targets 2/3rds of the time in a six months period.

The specific

requirements of the COPC standard and the suggested application of six sigma is

as follows:

1.3

Business strategies and plans – the

financial and non-financial targets can be converted to six sigma projects and

prepare an annual project plan.

1.4

Reviewing performance – six sigma

tollgates is an effective way of reviewing and the supporting the above

improvement plans.

2.1

Developing new CSP end-user

servicing capabilities – develop Critical-to-Quality (CTQs) and

Critical-to-Process (CTPs) based on Voice of Customer and Quality Function

Deployment (QFD).

2.2

Implementing new products, services,

programs and clients – DFSS approach completely address this requirement.

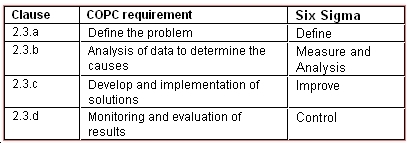

2.3

Process control – FMEAs can be used

to identify high risk KCRPs and make procedures to reduce the risk of failure

and thus ensuring consistent performance to clients.Further, control charts can be used to

achieve process stability.

2.4 Process improvement – the four step approach described in 2.3.3

is similar to the DMAIC approach. DMAIC is a structured and scientific approach

to find root causes.

2.6

Transaction monitoring – detailed

control plans can be developed to monitor the transactions.

2.6.2

Individuals performing the monitoring

calibrated – Accuracy, repeatability and reproducibility studies can be done to

qualify the quality analysts performing transaction monitoring

2.8

Contingency planning – the FMEAs can

be used extensively to prioritize the risks and plan steps to reduce the risk

to acceptable levels.

2.9

CUIKA: Performance data to be Collected, Usable, Integrity, Known to people and lead to Actions – Six Sigma is very strong in

data management. Appropriate statistical techniques can be used to convert the

basic data into information, and then it can be used by decision makers in a

better way.Further, measurement system analysis

(MSA) techniques can be used to quantify the data integrity measures.

2.10

Data Security – the FMEAs can be used

extensively to prioritize the risks and plan steps to reduce the risk to

acceptable levels.

|